Clamping workpieces without hydraulics, but there is not enough space in the machine?

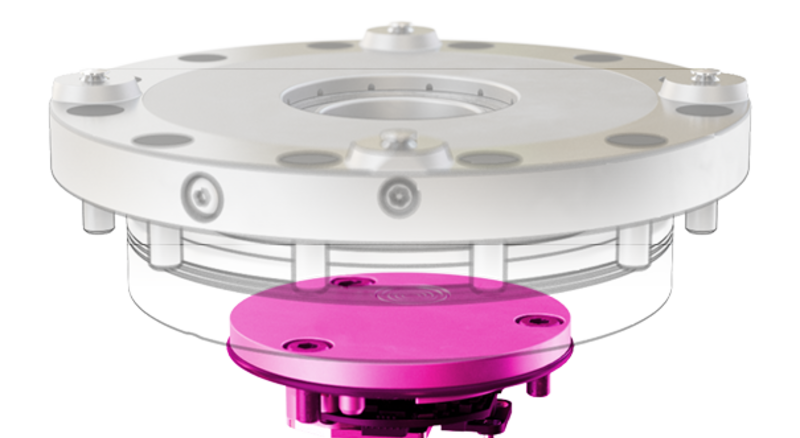

Because this is a recurring challenge, ROEMHELD has now presented a small version of its tried-and-tested electric swing clamp at EMO.

According to the company, the two versions are the only electromechanical swing clamps available on the market to date. Thanks to its compact size, the new product can be used in a wide range of applications.

In the new size 1, the model has a length of just 260 mm with a diameter of 55 mm. The axial tensile force is 2.7 kN and the clamping stroke is 13 mm.

Swivelling the clamping arm through 180° only requires an axial stroke of 3 mm. A swivelling angle of 90° is also possible.

Depending on the user's requirements, the swing clamps can be controlled individually or together. Disc springs allow the unit to be mechanically repositioned as required, ensuring precise clamping at all times. When unclamping, the clamping arm always swivels back to the starting position. A self-locking spindle drive ensures safe operation. If the power supply is interrupted, the clamping force is maintained.

Various features and function controls contribute to a high level of process reliability. The clamping force can be precisely adjusted and monitored. It also offers electrical position monitoring, clamping travel monitoring and various self-diagnostics. If required, all commands and information can be transmitted wirelessly using the optionally available IO-Link connection.

There is also an overload protection in the event of a collision with the clamping arm. In this case, the drive is automatically switched off immediately. The 24 V DC voltage used in the unit is classed as ‘low voltage’ and is therefore safe for people to touch.

A wear-free, brushless DC motor serves as the drive. The gearbox and a threaded spindle convert the motor rotation into a swivelling and lifting movement of the piston rod. The swing clamps are therefore particularly suitable for clamping workpieces whose clamping points must be free for loading and unloading the fixture.

The electric drive offers another special advantage compared to the hydraulic versions: The element is completely leak-free. It is also maintenance-free up to 500,000 cycles and, as a version with protection class IP67, is dust and water-protected.

The electronic control for the DC motor is housed on a circuit board in the housing of the swing clamp. The power supply and signal exchange to the external control unit are realised via two short cables with plug connectors. Cable sockets are available as standard for connection by the customer.

With their smaller size, the electromechanical swing clamps can now open up further areas of application. To date, they have mainly been used in testing technology, robotics - for example in electromechanical gripper systems - assembly technology or in special applications such as industrial furnace interlocks.

The new small size is also aimed at fixtures for classic machining and automation applications in machine tools.

In addition to electromechanical swing clamps, ROEMHELD also offers a wide range of hydraulic models.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.