Clamping elements

Clamps for assembly technology have to meet different requirements than, for example, clamps for machining. Priority is given to safe clamping; it is essential to prevent the workpiece from falling out.

Therefore, the capabilities of status indication / clamping sensing and self-locking are of particular importance.

Different drive energies can be used:

Manual, pneumatic; electric; hydraulic.

Due to the setup with a crane or by hand, pre-positioning and active retraction of the tensioner can be very important. From an ergonomic point of view, the tensioner should not form a shearing edge.

Single-acting, pneumatic

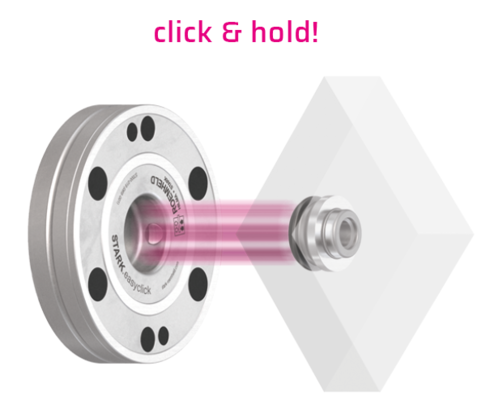

The STARK.easyclick is a mechanical quick-release fastener that clicks and holds immediately without energy supply.

To release it, it only needs an air connection with 4 - 8 bar pressure.

85 mm diameter and only 19 mm high

5 kN clamping force - 10 kN holding force

Release time 0.1 sec

Focus: Vertical arrangement;

Secure holding of workpieces on flat surfaces

with self-locking

max. clamping force 7.5 kN

max. clamping stroke 6 mm

Focus: Applications with workpieces with clamping lugs and optional turning in the application.

Due to the high clamping force and self-locking, the workpieces are also held securely during turning (device with corresponding design and safety consideration necessary).

The bore clamps B1.4841, B1.4842 and B1.4843 have a self-holding function and can be placed under the workpiece. They are therefore particularly interesting for 5-sided assembly.

What happens if the clamping pressure drops?

If the pressure drops, the workpiece is no longer pulled onto the hardened support. The radial spread of the clamping jaws and thus the positive fit with the workpiece are maintained by the spring preload.

Focus: Maximum accessibility to the workpiece.

Operation with 24V makes them particularly safe.

The voltage is self-locking.

A spring assembly safely compensates for minor setting effects.

The modern control electronics make it possible to monitor the clamping process.

Focus: Tension monitoring, self-retaining, hydraulic-free

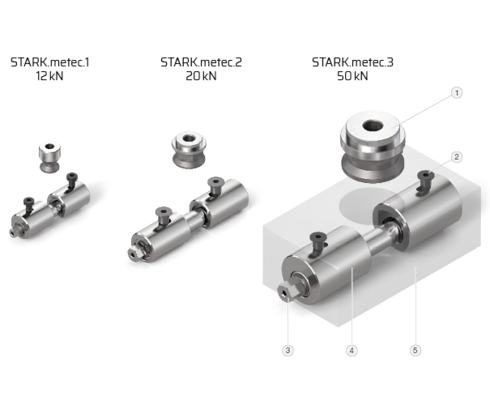

STARK.metec is a solid, mechanical Zero point clamping system that enables simple and cost-effective zero-point clamping solutions.

Focus: Mechanical clamping without external energy

3-point supports have already proven their worth. A wide variety of frame shapes can be clamped. The wide spacing of the mounting points reduces the forces at the support points and protects paintwork and sensitive materials. Particular emphasis was placed on edge and impact protection as well as a stable design and good accessibility.

The mount is designed for a bike weight of up to 40 kg.

Order no. 6352939

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.