In the compressor environment, assemblies are typically massive, highly varied and often need to be moved across several stations or production islands.

The device is designed for components weighing between 22 and 65 kg and is loaded by crane.

Typical objective: an assembly cart that not only transports goods but also actively saves assembly time.

Proven system concept in practice:

-

Mobile cart module (as an industrial-grade chassis) with defined connection for functional modules

-

Height adjustment for ergonomic access (e.g. for screwing, sealing, testing)

The component can be raised to an optimal working height over a stroke of 200 mm. This means that assembly work can be carried out predominantly in an upright position. - Rotation/swivel function for safe turning of the assembly without excessive force

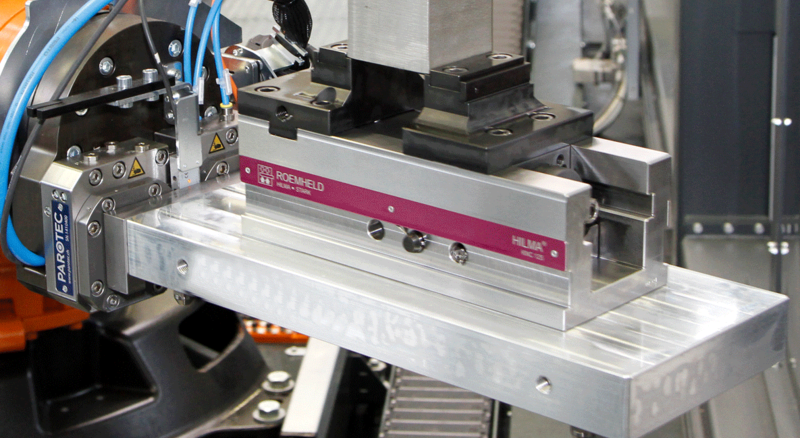

The component can be rotated continuously and also indexed precisely (4x90°). This allows defined assembly positions to be achieved reproducibly without releasing the tension. - Clamping and mounting concept: components are fixed in a manner appropriate to their shape and the process; variants are covered by interchangeable adapters

A grid mount covers workpiece diameters from Ø360 to Ø600 mm and sets the correct position for different sizes with repeatable accuracy. The workpiece is positioned using a plastic centre pin, which can be retracted for subsequent assembly tasks using a hand lever as soon as the component is clamped. - Kitting & tooling: tool holders, parts provision, optional error prevention through clear storage/positions

The effect in practice: less reaching around, less lifting, less ‘improvisation’ – and thus more stable cycle times and a noticeably smoother process.

The component is picked up once, aligned and remains accessible throughout the entire assembly process. There is no need for multiple removals, temporary storage or re-alignment.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.